Details

Drilling hole is one of the common metal cutting process, simple and direct. Drilling on the workpiece we expect to have holes is probably to locate and use the drill.

Deep hole definition:Will the depth of the drill hole had requirements for drill? Of course, the length of the drill must be greater than the hole depth, but also include the length of the machine tool hold requirements. The deeper the hole, the more difficult the drill, and the more requirements for the drill. What kind of drilling is called a deep hole drill? Usually we define the ratio of hole depth and hole size, that is, when the hole depth is a multiple of the diameter (depth diameter ratio) reaches 5 or more, we call it deep hole drill, for example, 4 mm drill, when the hole depth is 20 mm or more, we call it deep hole drill.

Drill:When making deep hole drills, we can usually choose a twist drill or a gun drill

Key points and process measures of deep hole drilling processing

1. The tool cutting situation can not directly observed when deep hole drilling processing , so can only listen to the sound, check the chips, observe the machine load and cutting fluid pressure and so on to judge the cutting wear and processing conditions.

2. The heat dissipation is difficute during the deep hole drill, so effective and reliable cooling method must be adopted.

3. The chip removal is another difficulties of deep hole drill, if chip clog happens may result in tool damage. To carefully choise cutting parameter is necessary to ensure chip broken reliable and discharge smoothly.

4. The deflection may happen on deep hole drill, hence guide or holder may required for tool and machine tool sturucture.

5. The drill rod is longer for deep hole drill, the poor rigidty & easy vibration will effect machining accurancy and production effiency. The reasonable cutting parameter will be critical.

Following technics may need to apply in deep hole drill:

1. To make a shallow hole with same diameter before drill, it will be directive centering function during drill. This step is especially necessary when machining small holes with high straightness requirements.

2. To ensure that the central axis of the workpiece hole coincides with the central axis of the drill pipe.

3. Based on the working pieces’ materials to set cutting parameters to achieve C type or similar chips.

4. When machining high strength materials, try lower cutting speed. The feed rate will be most important effect for chip. Lower feed rate are preferred.

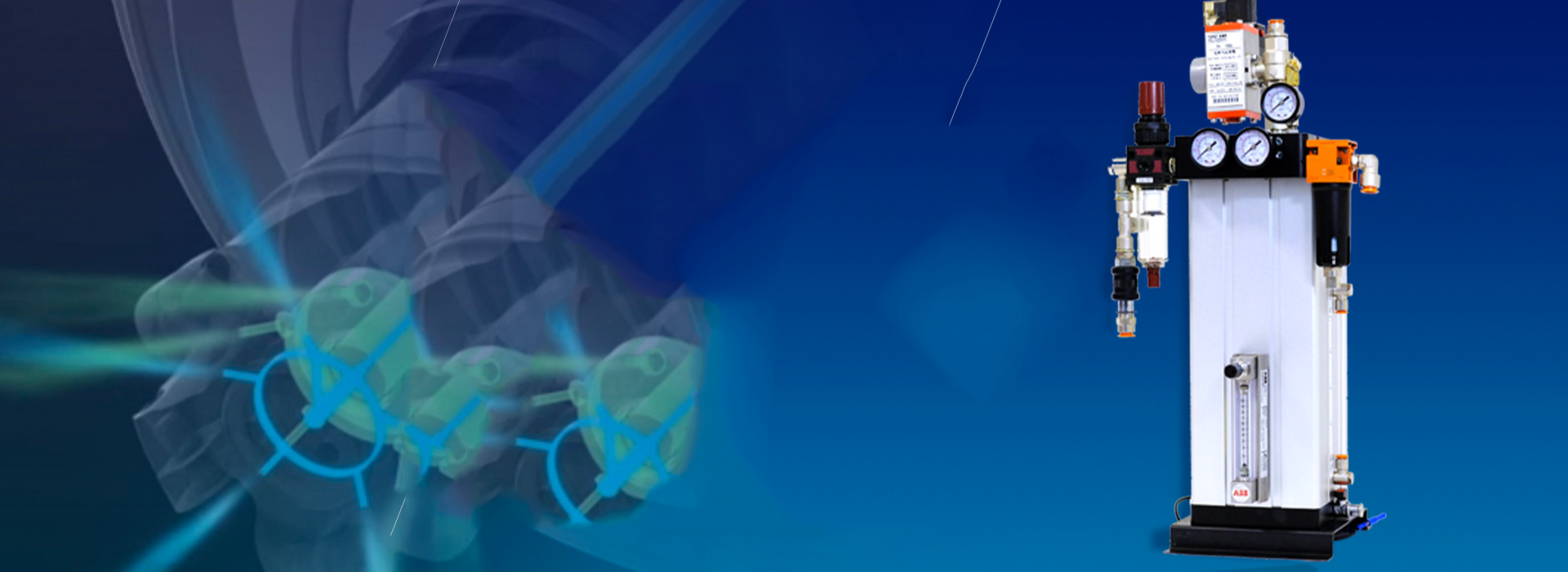

5. Cutting fluid with proper pressure and flow will be benifity for cooling and chip discharge. Small deep hole required high pressure, low flow. Larger deep hole prefer low pressure and high flow.

6. To start cutting fluid pump in advance and then drill, If fault happen, stop tool first and then stop machine tool, to stop cutting fluid pump finally.

All above key points under cutting fluid will be work under MQL near dry machining?

The Near Dry Machining (NDM) was using Minimum Quantity Lubrication(MQL) to replace cutting fluid cycling system in metal cut process. The minimum lubricant will be feed to drill tip through tool’s inner cooling chamber and spindle. The lubricant and compressed air will provide lubrication, cooling and chip discharge assistance for tool, work pieces and chips. The details of chip discharge and cutting temperature are as follows:

1. When twist drill: The chip removal main rely on chip well creaked into enough small. The compressed air of MQL unit will be main motive power of discharge chip from inside hole.

2. When gun drill: The chip removal main rely on chip well creaked into enough small. The compressed air of MQL unit will be main motive power of discharge chip from inside hole.

The two are exactly the same.

Temperature:

During Near Dry Machining(NDM), the lubricant will control friction heat,plastic deformation heat will be transmitted to chips, tool, and work pieces. The cooling effect of compressed air far poor than cutting fluid, hence, the temperature of chip, tool and work pieces will increase in different degrees. This is the mechanism basis of longer tool life.

Application data from TOPSET on engine manufacturer :

|

Work pieces materials |

Drill Brand |

Drill size |

Hole quantity-hole diameter-hole depth |

Compressed air pressure |

Tool life in hole q’ty |

Cutting Parameter |

Cutting cycle |

|

42CrMoS4 |

HENGKETE |

φ5-151mm |

4-φ5-110mm |

6bar |

130 |

S=2800;F=0.1;S退=500 |

5'//" |

|

QT750-3 |

WALTER |

φ6-165mm φ4.5-165mm |

2-φ6-48.5mm (Straight) 4-φ4.5-130mm(Decline) |

6bar |

140 |

S=3000;F=450;S退=1000 S=3600;F=450;S退=1000 |

5'//" |

|

铸铁 |

φ8-HENGKETE φ6-GUHRing |

φ8-113mm φ6-165mm |

4-φ8-87mm (Straight) 4-φ6-110mm(Decline) |

6bar |

10 more; 30 more; |

S=2500;F=495;S退=1000 S=4000;F=360;S退=1000 |

8'42" |

|

QT640-2 |

φ8-OSG φ6-GUHRing |

φ8-//mm φ6-//mm |

4-φ8-60mm (Straight) 4-φ6-102mm (Decline) |

6bar |

200 more |

S=2800;F=0.13;S退=720 S=2800;F=0.1;S退=720 |

7'45" |

|

QT900-5 |

φ6-GUHRing φ7-WALTER |

φ8-180mm φ7-//mm |

4-φ6-116mm(Decline) 4-φ7-81mm (Straight) |

5bar |

100 more; 200 more |

S=2850;F=0.162;S退=475 S=3134;F=0.187;S退=475 |

5'30" |

|

42CrMo(A) |

GUHRing |

φ8.8-223mm |

6-φ8.8-150mm |

With Boost pump |

40 more+50 more=90 more |

S=2200;F=0.15;S退=700 |

6'10" |

|

45 |

GUHRing |

φ8-223mm |

12-φ8-150mm |

With Boost pump |

60-70 |

S=3000;F=0.168;S退=// |

6'12" |

|

30104 |

GUHRing |

φ7-165mm |

6-φ7-132mm |

6.3bar |

70-80 |

S=2000;F=0.17;S退=600 |

5'25" |

|

C38+N2BY |

HENGKETE |

φ7-202mm |

6-φ7-152mm |

6.3bar |

30-40 |

S=2300;F=0.165;S退=750 |

5'47" |

|

48MoV |

HENGKETE |

φ7-165mm φ8-183mm |

6-φ7-112mm(Decline) 6-φ8-85mm(Straight) |

6.0bar |

60-70 more |

S=2000;F=0.136;S退=1000 S=2000;F=0.17;S退=800 |

9'28" |

|

48MoV |

HENGKETE |

φ7-165mm φ8-183mm |

6-φ7-112mm(Decline) 6-φ8-85mm(Straight) |

6.0bar |

70-80 more |

S=2000;F=0.144;S退=1000 S=2000;F=0.18;S退=800 |

8'44" |

|

48MoV |

GUHRing |

φ7-165mm φ8-183mm |

6-φ7-112mm(Decline) 6-φ8-85mm(Straight) |

6.2bar |

Average 52 |

S=2000;F=0.114;S退=800 S=2000;F=0.152;S退=800 |

10'24" |

|

铸铁 |

φ6-OSG φ7-WALTER |

φ6-165mm φ7-150mm |

4-φ6-80mm(Decline) 4-φ7-110mm(Straight) |

6.0bar |

100 more |

S=2600;F=0.19;S退=800 S=2400;F=0.19;S退=800 |

6'20" |

|

42CrMo(A) |

φ8-HENGKETE |

φ8-105mm |

6-φ8-105mm 6-φ8-85mm |

6.0bar |

20-30 more |

S=2300;F=0.123;S退=// |

10'58" |

|

42CrMo(A) |

φ8.8-GUHRing |

φ8.8-157.5mm |

6-φ8.8-157.5mm |

6.0bar |

60-70 more |

S=2500;F=0.2;S退=// |

7'04" |

Application data from TOPSET on general manufacturer :

|

Work piece |

Material |

Process |

Tool and specification |

Parameter |

Tool life |

|

camshaft |

16MnCr5 |

Centering |

D = 6,3 x 20 |

N = 500 min -1 |

1200centres |

|

|

Vf = 50 mm/min |

||||

|

camshaft |

16MnCr5 |

Drill |

Step drill, |

N = 2 800 min -1 |

2400 holes |

|

D = 6,8 x 10 x 28,5 |

Vf = 504 mm/min |

||||

|

camshaft |

16MnCr5 |

Reamer |

D = 7 H8 |

N = 690 min -1 |

1 200 operations |

|

Vf = 152 mm/min |

|||||

|

crankshaft |

38MnVS5 |

Drill |

HSS-Drill |

N = 330 min -1 |

500 holes |

|

D = 14,5 mm |

Vf = 52,8 mm/min |

||||

|

crankshaft |

38MnVS5 |

Countersinking |

HSS-countersink |

N = 90 min -1 |

960 operations |

|

90 ° |

Vf = 5,2 mm/min |

||||

|

crankshaft |

38MnVS5 |

Threading |

Tap |

N = 90 min -1 |

500 threads |

|

M16 x 1,5 |

Vf = 135 mm/min |

||||

|

cylinder head |

Al Si 7 Mg |

Saw |

Band saw |

|

> 2 000 cuts |

|

cylinder head |

Al Si 7 Mg |

Milling |

Surface milling |

|

Approx. 6 000 |

|

universal-joint spindle |

CK 45 |

Drilling |

HSS-Drill |

N = 200 min -1 |

100 – 150 holes |

|

(Impact drilling) |

D = 14 mm |

Vf = 40 mm/min |

|||

|

Shaft |

20MoCr4 |

Rolling |

Rolling tools |

|

40 – 50-thousand |

|

DIN profile |

|||||

|

cylinder head |

Al Si 10 Mg |

Milling |

End mill |

N = 4 000 min -1 |

Approx. 105 000 |

|

Vf = 1 200 mm/min |

|||||

|

cylinder head |

Al Si 10 Mg |

Milling |

Surface mill |

|

Approx. 3 500 |

|

connecting rod |

|

Thread grooving |

Thread grooving |

N = 190 min -1 |

1 500 Threads |

|

M16 x 1,5 |

Vf = 285 mm/min |

||||

|

crankcase |

Al Si9 Cu3 |

Deep hole drilling |

Deep hole drill |

|

5 000 holes |

Application data from TOPSET :

|

Machine Tools |

Crankshaft oil hole machine center |

|

Tool supplier |

OSG |

|

Twist drill-size |

5mm X 200mm |

|

Work piece |

Crankshaft |

|

Materials |

FCD700 |

|

Spindle speed |

3600r/min |

|

Feed rate |

0.16mm/rev |

|

Feed speed |

576mm/min |

|

Drill length(Straight) |

92×2=184mm |

|

Drill length(Decline) |

100X 2=200mm |

|

Lubrication |

MQL |

|

Compressed air pressure |

9bar |

|

Tool life |

200 pcs crankshaft(800 hole) |