CUSTOMERIZED MINIMUM QUANTITY LUBRICATION SYSTEM FOR OILING ROLLS, BLAD&MODEL, GUIDE

Classification:

Details

System Concept Design

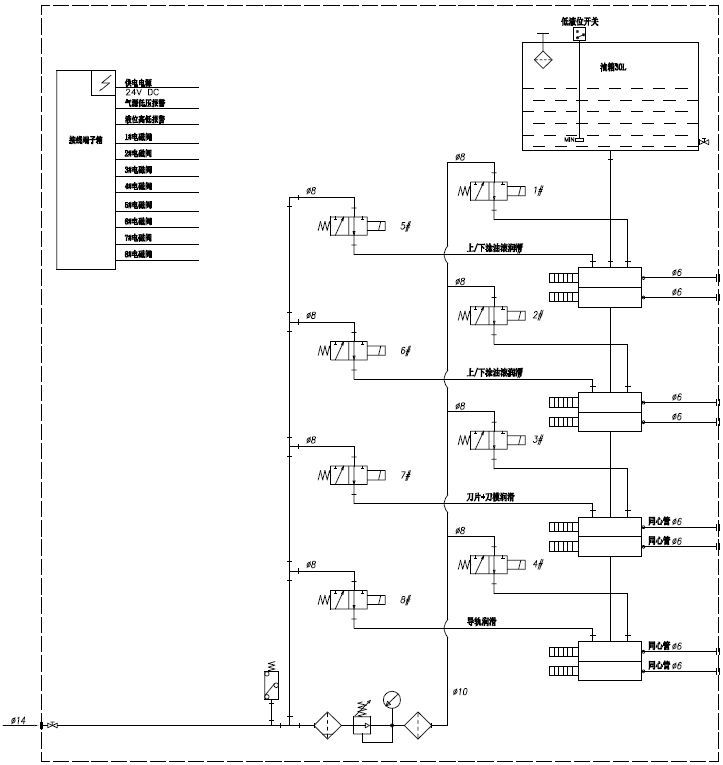

Description of the control principle of the MQL system:

After the inlet valve of the compressed air system is opened, the MQL system ready for working. The S-200 programmable controller will be core of control. The powe supplied by the host machine. Red indicator means normal conditions and yellow flash shows system fault.

When power “ON”, the controller will enter pre-lubrication automatically. It run all mini pump as per preset cycle and blowing each point by compressed air. Then, the MQL system ready for working and communication with host machine.

The control principle of the MQL system:

- The upper and lower oiling roll will be one group. Them will be “on/off” same time.

- Oiling roll A, B and C controlled seperated.

- Blade and model will be one group.Them will be “on/off” same time.

- Peumatic Guide will be self alone.

Oiling roll A start, Host machine command “A on”, MQL system run mini pump to feed oil to oiling roll A upper and down side. And so on for oiling roll B and C. Same control logic for blade and model, peumatic guide.

The cycling for oiling roll, blade&model, guide could be set individually. When compressed air pressure go down below the setting value, the alarm will sent to the host machine.

When oil level goes down below the settting value, the alarm will sentto the host machine.

Picture show:

Oil tank and mini-pump

Panel arrangement

Inside piping and wiring

Send your question or inquiry to sales@topset.com for your MQL lubrication solutions.