CUSTOMERIZED MINIMUM QUANTITY LUBRICATION SYSTEM FOR FRICTION PAIR & OPEN GEAR

Classification:

Details

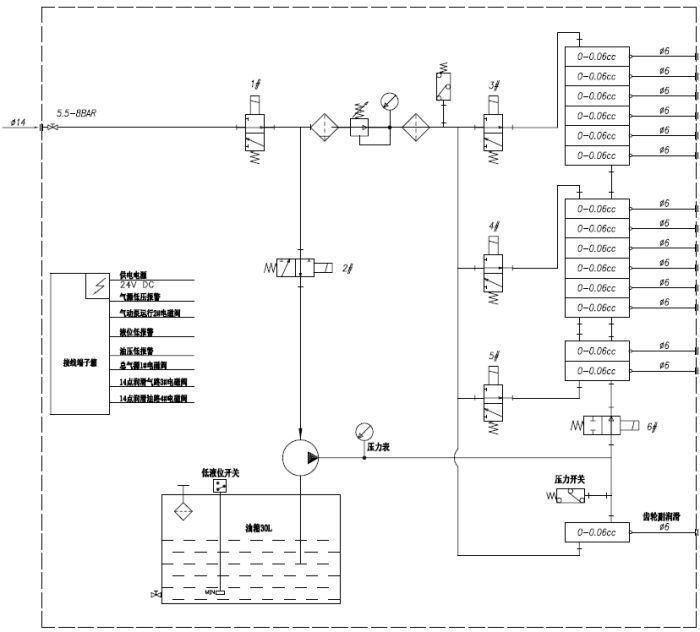

System Concept Design

Description of the control principle of the MQL system:

The MQL system feed a small amount of lubricating oil (4-5 drops / hour) to 14 points of machine and provides microlubrication to the semi-dry gear pair.

The 4-7Bar compressed air comes from the centralized compressed air pipeline system at site. The 1# solenoid valve switch on/off the air supply when receiving the command of the host control system,

1 # lubrication system takes S-200 programmable controller as the control core, the power is supplied by the host, the normal indicator is red, and the system fault indicator is yellow strobe.

When the host control system gives the "lubrication open" instruction, the MQL system will:

1、Open the 1 # solenoid valve, and the compressed air starts blowing the gear pair.

2、Control the "open" and "off" of 2 # solenoid valve according to the pre-lubrication rhythm, and control the pneumatic pump to deliver lubricating oil to the lubricant pipeline, and 6 # solenoid valve = is in the "open" position to supply oil to 14 points.

3、The system enters the pre-lubrication to feed the oil, and the MQL system starts the pre-lubrication timing.

(So-called pre-lubrication is: when receiving the "lubrication open" instruction, open 1 #, 3 #, 4 #, 4 #, 5 #, 6 # valve, 2# valve will be controlled as per the pre-lubrication rhythm, then detect the oil pressure switch, air pressure switch, oil level, if normal to allow the host start production, if not to shut-off all valve and alarm at the same time.)

4、After the pre-lubrication recycle, the MQL system gives the "ready" signal to the host machine to allow the host to "start" production.

5、At the same time, the MQL system run the lubrication programly to ensure the oil supply.

When the host system gives the "Lubrication off" instruction MQL system:

- Immediately shut-off the 1# valve and cut off the compressed air supply.

- Shut-off 2# valve and stop oil pump.

- Shut-off 3#,4#, 5#, 6# valve.

When the "lubrication on" command is received again, the MQL system will start according to the above procedure and directly enter the lubrication cycle.

Picture show:

Oil pump

Push button arrangement

Inside piping &Wiring

Send your question or inquiry to sales@topset.com for your MQL lubrication solutions.